Slime build-up is an expensive drag on gasoline effectivity for ocean-going cargo ships, leading to additional emissions and, lastly, elevated shopper prices. A modern study, nonetheless, suggests a model new technique to managing this widespread draw back.

Researchers at KTH Royal Institute of Experience developed a model for estimating the speed and extent of biofilm progress, which can permit ship operators to schedule hull cleaning at optimum intervals to avoid wasting numerous on gasoline consumption.

Cornelius Wittig, a PhD scholar in fluid mechanics at KTH, says the study provides a first-ever rationalization of how shear stress interacts with biofilms over time to foster slime fouling on surfaces such as a result of the hull of a ship.

The fouling course of begins with micro-colonies of micro organism attaching to a ground. These micro organism sort base constructions from which string-shaped streamers begin to develop. Collectively, the underside constructions and streamers combine to sort ground imperfections that lead to friction between the hull and water. Streamers develop and imperfections assemble up at completely totally different fees counting on the extent of stress induced by fluid circulation in the direction of the ground.

Slime fouling gives significantly to fluid friction at sea – requiring an increase in a vessel’s shaft power by as lots as 18 p.c, talked about Wittig. “A ship coated with a thin biofilm may experience as a lot as an 80 p.c enhance in gasoline consumption.”

In numerous circumstances a ship doesn’t get scheduled for cleaning until the operator sees a spike in gasoline consumption, he says. “By then it’s too late and a wide range of gasoline has been wasted.” So with a objective to reap some great benefits of de-fouling a ship, timing is necessary, he says.

“The potential gasoline monetary financial savings gained by cleaning needs to be good ample to offset the costs of the dry-dock and cleaning procedures,” he talked about. “Appropriate predictions would allow for setting pleasant scheduling of cleaning for ship operators.”

He says additional evaluation is required in further actual wanting conditions sooner than the model could be utilized in supply. The proof displays that shear stress will probably be roughly estimated just by determining the speed of a ship. “From a ship operator’s perspective, it is attention-grabbing to know if the ship must be cleaned in subsequent month or subsequent 12 months, so an estimate is ample to increase the accuracy of their alternative making.”

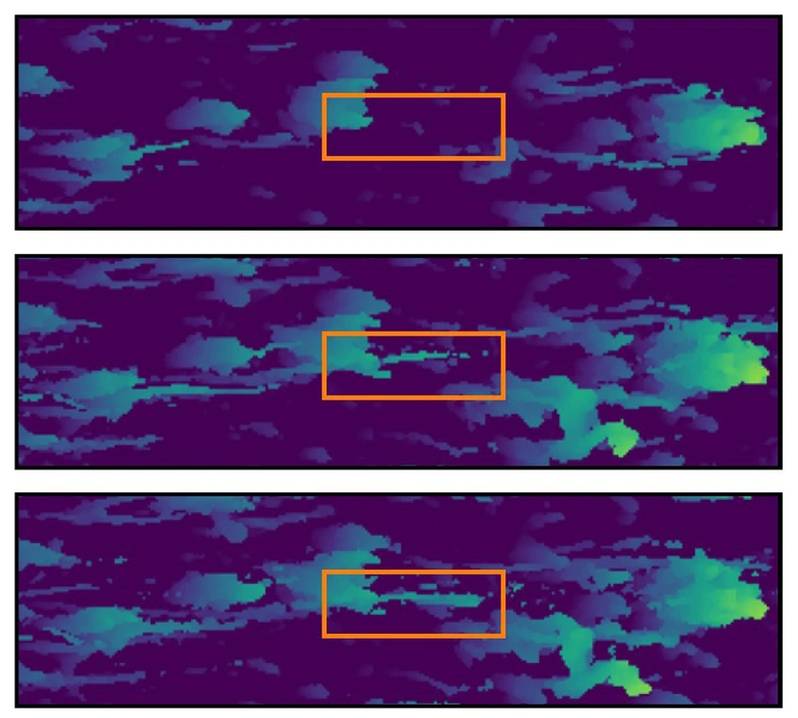

The evaluation was revealed throughout the journal, NPJ Biofilms and Microbiomes. The formation of biofilm over three days (starting from the very best) will probably be seen in these photos from the laboratory. Image courtesy KTH Royal Institute of Experience

The formation of biofilm over three days (starting from the very best) will probably be seen in these photos from the laboratory. Image courtesy KTH Royal Institute of Experience